Greenhouse Gas Emissions - Sustainability.ussteel.com

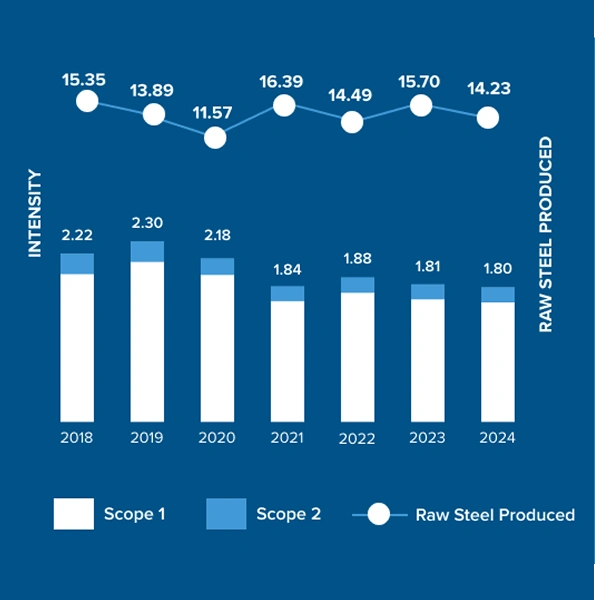

Although producing steel is carbon-intensive, we have a roadmap, featured in our Climate Strategy Report, which outlines our vision to get to net-zero Scope 1 and Scope 2 emissions by 2050. Roughly three-quarters of the greenhouse gas (GHG) emissions from integrated steelmaking are associated with the use of coke and coal to chemically reduce and melt iron in blast furnaces. U. S. Steel has always strived to be on the leading edge of the most energy-efficient production of steel using blast furnaces. Further, we are making steel by melting recycled steel scrap using electricity in electric arc furnaces (EAFs), significantly reducing GHG emissions and creating opportunities for renewable energy use. U. S. Steel recognizes the importance of both steelmaking technologies in its operations while transitioning to a lower carbon economy.

Our progress toward lowering Scope 1 and Scope 2 emissions continued through 2024 with important milestones. For example, in October 2024, U. S. Steel started up its second mini mill, BR2, which will reduce our GHG emissions intensity once operating at run-rate capacity. U. S. Steel has invested in multiple renewable energy projects and efficiency improvements at our facilities, also contributing to our lowered Scope 2 emissions. Our absolute Scope 1 emissions decreased to 22.83 million metric tonnes in 2024 from 25.84 million metric tonnes in 2023, while our Scope 2 emissions increased to 2.78 million metric tonnes in 2024 from 2.55 million metric tonnes in 2023.

As part of our commitment to continuous improvement, we identified opportunities to enhance our GHG data collection, calculations and analysis processes. This effort led us to update our global warming potentials to the AR54 version to match U.S. Environmental Protection Agency (EPA) reporting. We also localized our emissions and energy factors where information is available, preferencing local or regional data over global averages. Lastly, we updated our Scope 2 calculation methods for both location- and market-based emissions. Because of these changes, we are restating our GHG emissions going back to our baseline year of 2018, including the intervening years, as shown here and in our data tables.

Visit our GHG emissions-related highlights, goals and progress.

Raw Steel Produced Units: million metric tons

The GHG emissions intensity is based on the total quantity in metric tons of GHG emissions calculated in accordance with GHG Protocol and EU ETS standards divided by the total quantity in metric tons of raw steel produced globally as published in the U. S. Steel Annual Report and that is processed into finished steel products

Scope 3 Greenhouse Gas Emissions

| Metric | Emission Unit of Measure |

|---|---|

| Category 1 - Purchased Goods and services | 11.01 Million metric tonnes |

| Category 2 - Capital Goods | 0.28 Million metric tonnes |

| Category 3 - Fuel & Energy-related Activities not in Scope 1 or Scope 2 | 5.05 Million metric tonnes |

| Category 4 - Upstream Transportation & Distribution | 0.61 Million metric tonnes |

| Category 6 - Business Travel | 1,900 Metric tonnes |

| Category 7 - Employee Commuting | 24,427 Metric tonnes |

| Category 9 - Downstream Transportation & Distribution | 0.35 Million metric tonnes |

| Category 10 - Processing of Sold Products (Steel Products Only) | 0.39 Million metric tonnes |

How We Are Advancing Toward Net-Zero

We have undertaken and planned several initiatives that will advance our progress toward our net-zero goal.

Direct-reduced iron (DRI)

DRI reduces our reliance on carbon-intensive coal and coke. DRI conventionally uses natural gas, but hydrogen based DRI is an emerging technology that can further reduce our direct GHG emissions.

Mini mills

Our Big River Steel Works and Fairfield Tubular mini mill plants use EAFs to melt scrap steel and use it as a key component of new steel, reducing emissions and cost. The new BR2 mini mill uses the same technology, increasing our recycling capability in addition to producing on average 70% to 80% less Scope 1 and 2 GHG emissions per ton of steel than a conventional integrated mill, which relies on blast furnaces and basic oxygen furnaces.

Process optimization

Process models are helping us increase efficiencies in our current steel mills, reducing emissions.

Clean locomotives

In April 2024, U. S. Steel received the Pennsylvania Governor’s Award for Environmental Excellence for our innovative conversion of two of our diesel locomotives to battery power for use at the Clairton and Edgar Thomson Plants. The conversion project, launched in partnership with the Pennsylvania Department of Environmental Protection, is expected to reduce air borne particulate matter (PM2.5) emissions at the facilities by .385 tons — an amount equivalent to the emissions produced by 7,000 gasoline powered passenger vehicles.

Electrical grid advances

Improvements to the grid, including the addition of more green energy, will lead to a reduction in Scope 2 emissions and enable Scope 1 reductions.

Renewable energy

Solar power and other types of renewable energy are increasingly helping to power our facilities, and we’ll continue to look for ways to increase our renewables usage, as with the Entergy Arkansas Driver Solar project at U. S. Steel’s Big River Steel Works.

Carbon capture

Another emerging technology, carbon capture promises to reduce our steelmaking CO2 emissions by grabbing CO2 out of our process gas waste streams, so that it can be stored, or utilized in a variety of ways.

Offsets and credits

Any remaining emissions reduction gaps can be offset through the attributes of verified carbon credits.

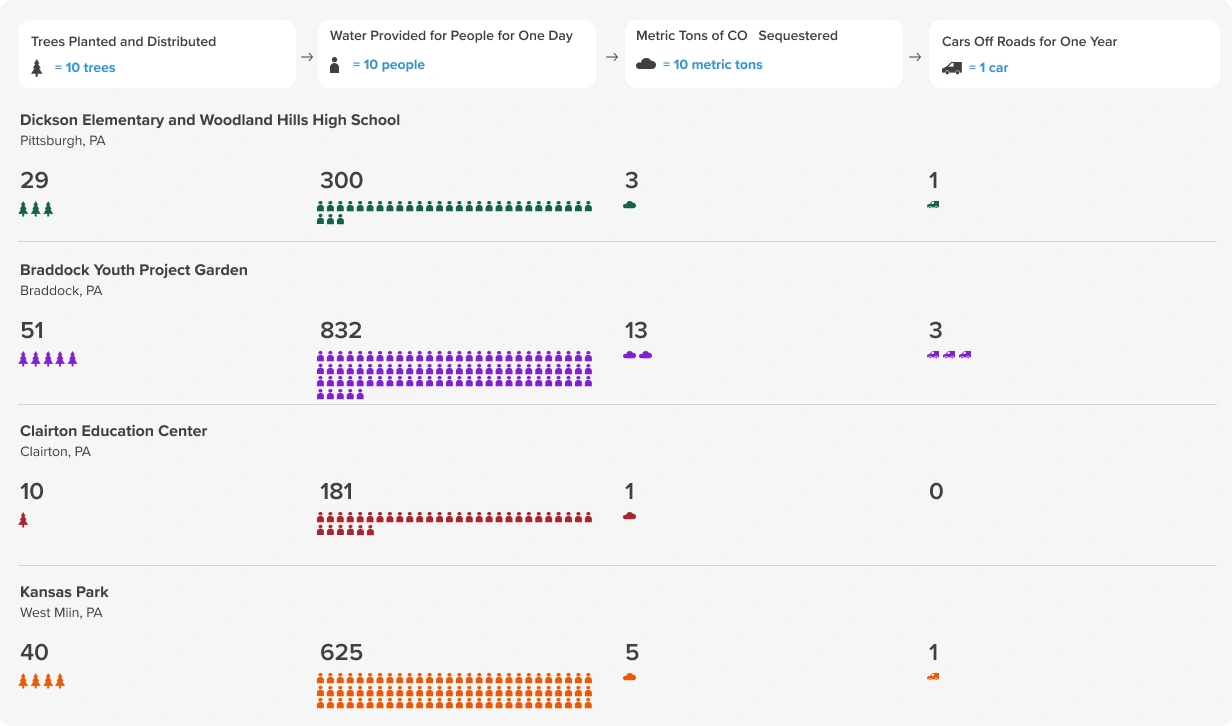

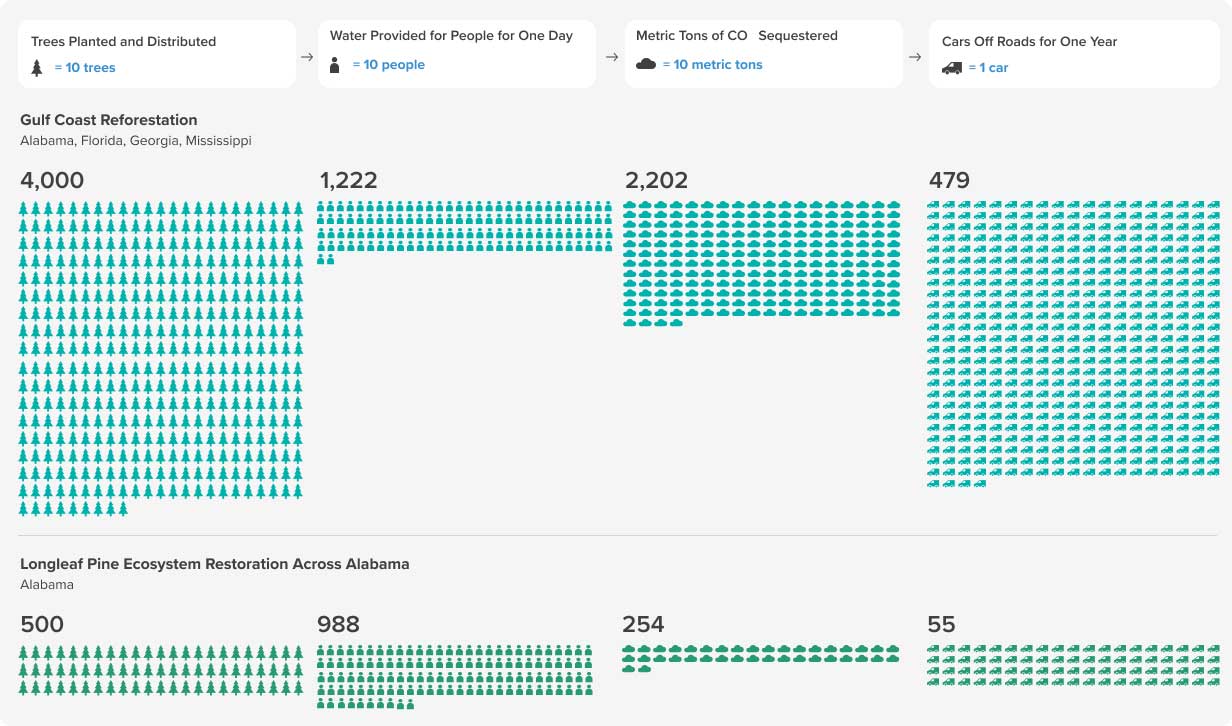

Tree Planting

U. S. Steel’s impact with the Arbor Day Foundation is measurable and lasting. Trees and forests are a proven solution to addressing some of the most pressing issues facing people and our planet. These challenges include climate change, water quality and quantity, biodiversity health, human health and environmental inequalities. This tool aims to showcase the impact that U. S. Steel and the Arbor Day Foundation have had together to address these issues. We are immensely grateful for the opportunity to collaborate to make a positive impact together.

Total projects

Acres restored

Trees planted and distributed in 2024

Metric Tons CO2 sequestered

Reforestation Efforts

Community Volunteering Efforts