Energy - Sustainability.ussteel.com

We are committed to minimizing our consumption of purchased non-renewable energy. To achieve this goal, we are pursuing multiple pathways, including process innovations, transitioning to renewable energy sources and enhancing energy efficiency beyond steelmaking operations. At our integrated plants, for example, we use coke oven gas and other gases generated in our furnaces to generate power and steam, thereby optimizing our energy use and reducing our carbon footprint.

We have set and maintain specific energy targets and goals. Visit our Energy-related highlights, goals and progress.

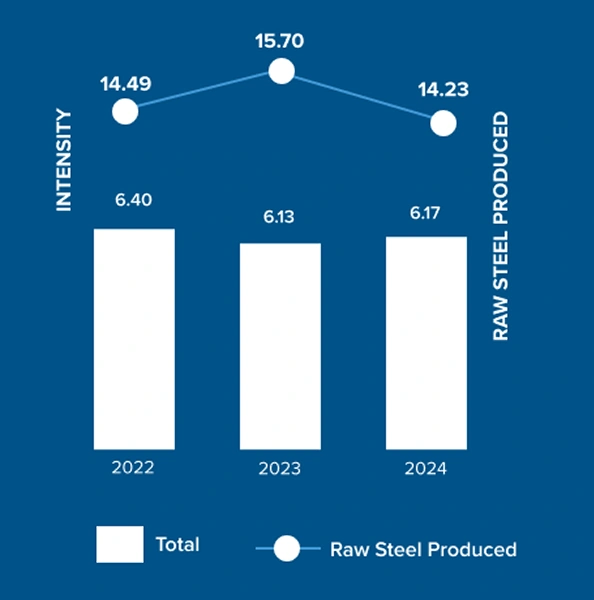

Raw Steel Produced Units: million metric tons

Energy intensity is based on the total energy consumption in megawatt hours divided by the total quantity in metric tons of raw steel produced globally as published in the U. S. Steel Annual Report and that is converted into finished steel products.

Our Energy Stories

At the Gary Works facility, blast furnace gas is used to fire the stoves that preheat the air going to the blast furnace. The remaining gas goes to the boiler house, generating steam for the turbines that supply wind to the furnace, meet steam needs for operations, and power our steam turbine generator to produce electricity. In 2024, Gary Works averaged 102.7 MWh of energy production, equaling 51% of energy needed to power the facility’s operations, through the reuse of the blast furnace gas.

Additionally, Gary Works provides the cement industry with granulated blast furnace slag (GBFS) as a direct substitute for clinker, reducing the cement industry’s Scope 1 and upstream Scope 3 emissions. Clinker production is highly carbon-intensive due to the calcination of limestone, which releases significant amounts of CO2. By substituting a portion of clinker with GBFS, the overall clinker content in cement is reduced. GBFS requires less energy to process compared to clinker, leading to lower CO2 emissions from fuel combustion during cement production.

The Mon Valley Works Edgar Thomson facility has two generators that together produce about 1,500 MWh daily, yet only half the energy is used at the facility. The rest is fed to the Mon Valley power grid, owned and operated by U. S. Steel, supplying energy to the Irvin and Clairton facilities. Operating our own power grid means purchasing less electricity, which reduces Scope 2 emissions and increases efficiency and reliability. Additionally, U. S. Steel’s coke oven gas (COG) distribution pipeline distributes the extra COG produced at the Clairton facility to the Irvin and Edgar Thomson facilities to be used as a fuel source. Our average extra COG production is 80–90 million cubic feet per day (MMCFD) — enough to heat 44,000 homes.

Alternative Energy

Origami Solar will use our ZMAG steel to manufacture solar panel frames to be utilized in solar fields. This will allow for cost reduction and increased reliability of solar frames. By enlisting domestically produced steel instead of imported aluminum for its frames, Origami will also be sharply reducing the GHG emissions associated with manufacturing the frame material.

Click on the icons on the map to learn more