Material Development - Sustainability.ussteel.com

At U. S. Steel, in addition to developing new grades and applications of steel products, we are also meeting our customers’ CO2 footprint challenges for the steel they use as we create the lower-carbon-intensity steels of tomorrow with the same tenacity and adaptability that has brought our steel solutions to life for more than 100 years. Our customers trust our highly skilled talent and advanced capabilities to create innovative products and specialty solutions for their ongoing and emerging requirements.

Advanced Products

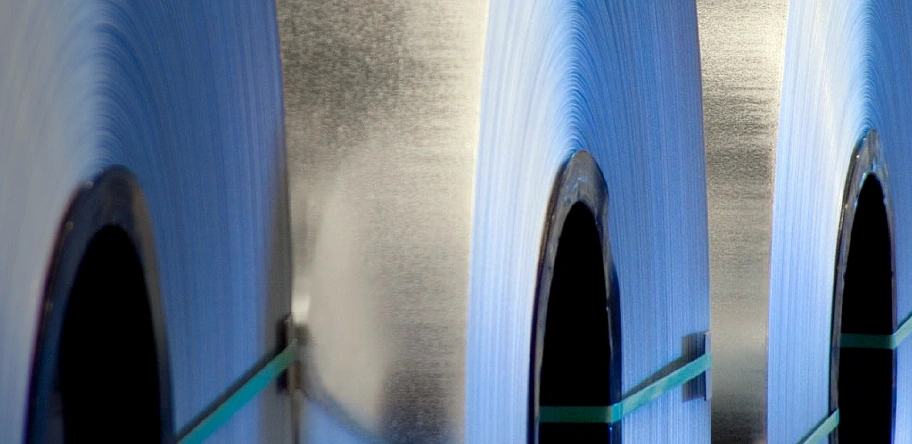

In 2024, U. S. Steel introduced ZMAG™ steel, an exciting new coated carbon flat rolled steel product featuring a unique zinc-aluminum magnesium coating. ZMAG™ steel is engineered to be strong, more resilient and more sustainable than products on the market today, and with a 25-year warranty, it is ideal for the demands of the domestic solar industry. ZMAG™ steel’s innovation brings a level of corrosion resistance that allows withstanding decades of harsh weather across most U.S. climate zones, unlocking new applications of domestic steel to meet evolving industry needs. The extended life of the product enables customers to meet their material use and life cycle goals and can offset CO2 emissions by delaying the need for replacement. And because the ZMAG™ coating is lighter than conventional coatings, it is produced with lower CO2 emissions.

We combined our GALVALUME® with DuPont™ Tedlar® polyvinyl fluoride (PVF) film to produce a maintenance free and highly sustainable roofing and siding solution, designed to meet the special durability needs of residential and commercial construction projects subject to harsh coastal conditions. COASTALUME™ offers as much as a 73% reduction in CO2 footprint compared to a comparable aluminum roof.

This wide, ultra-thin and light weight steel offers all the magnetic properties necessary for electric vehicles (EVs), as well as for generators and transformers. These optimized magnetic properties increase EV motor efficiency, leading to better mileage and range. InduX™ is produced on the new non-grain-oriented (NGO) electrical steel line at U. S. Steel’s Big River Steel in Osceola, Arkansas, representing a significant investment in American jobs and bolstering the resilience of the country’s domestic supply chain.

A third-generation hot-dipped galvanized steel for automakers, XG3™ offers a unique balance of high strength and high ductility. XG3™ products are in volume production for our automotive customers, helping them to achieve their weight-reduction and performance goals. XG3™ grades, available in strength levels from 780 to 980 megapascals (Mpa) from our newest line at PRO-TEC Coating Company, are an important part of U. S. Steel’s broad portfolio of Advanced High-Strength Steel products. By enabling weight reduction, XG3™ helps our automotive customers meet their goals for reducing GHG emissions in their vehicles.

U. S. Steel’s low-carbon-footprint product reduces steel’s carbon intensity by about 70% compared to traditional blast furnace steel, while containing up to 90% recycled content. It is also endlessly recyclable without degradation.

U. S. Steel Tubular Products’ USS-EAGLE TC™ was designed to meet the ever-increasing demands placed on casing connections in extended-length, horizontal shale gas wells. USS-EAGLE TC™ provides gas-tight metal sealing, 100% pipe body performance rating and extreme torque capacity.