Process Improvements - Sustainability.ussteel.com

We are also incorporating proprietary automated analytics tools and monitoring systems to optimize our products and systems. Advanced analytics have helped us assess product lifespans, improve our emergency response and reduce our carbon emissions, supporting values across our S.T.E.E.L. Principles.

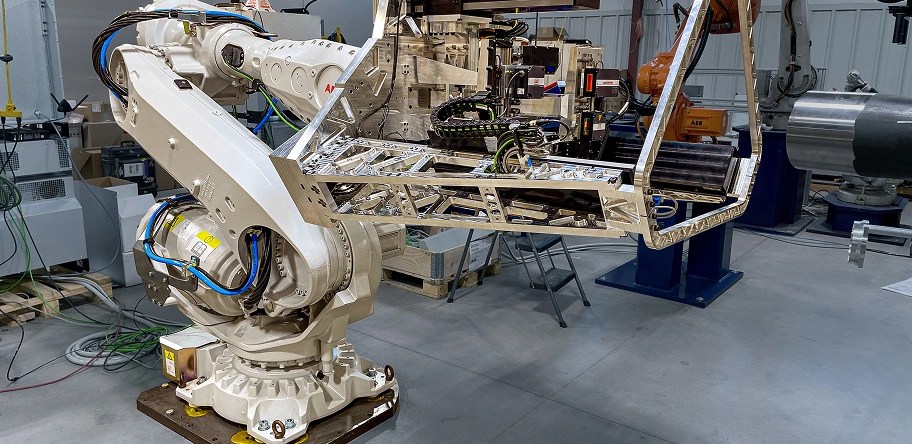

We have undertaken a variety of advanced process improvement projects:

In May 2024, U. S. Steel concluded a $150 million strategic investment project at our Minnesota Ore Operations Keetac taconite plant, having added the capability to produce direct reduced- grade (DR-grade) iron ore pellets. DR-grade pellets supply a key input for the feedstocks used in lower-emissions electric arc furnaces (EAFs), improving their quality and efficiency. The successful completion of this investment was commemorated with a ribbon cutting ceremony. The historic event, themed “Made in America, Made for the Future: A Strong America Starts with U. S. Steel,” was attended by state and local officials, including Minnesota Governor Tim Walz as well as local United Steelworkers leadership, suppliers, key collaborators, Keetac employees and U. S. Steel senior leaders.

The project represents an important step in U. S. Steel’s metallics strategy, helping to meet our own and customers’ needs in an increasingly tight DR-grade pellet market with low-cost iron ore. The new production facility at Keetac — which was completed in 2023 on time, on budget and after 300,000 hours of injury-free work — will also be able to produce blast furnace iron ore pellets, allowing adjustments to changing market conditions.

This artificial intelligence (AI)- driven application simplifies equipment maintenance by providing optimal solutions for mechanical problems, saving time and money and improving productivity. MineMind™ harnesses the power of Google Cloud’s generative AI technology as a secure app, running alongside the maintenance teams’ existing technology and solutions. It has been expanded to various equipment types to assist our maintenance teams at Minnesota Ore Operations at Minntac and Keetac. Together we’ve reduced work order times by up to 20% in 2024, improving productivity while enhancing the employee experience.